Insight Blog

Agility’s perspectives on transforming the employee's experience throughout remote transformation using connected enterprise tools.

17 minutes reading time

(3375 words)

How PLM Software Transforms Collaboration Between Design and Production Teams

Discover how PLM software boosts design and production team collaboration, streamlines workflows, and enhances product quality. Explore key benefits and implementation tips.

In 2023, the global market for product lifecycle management (PLM) software hit $26.7 billion, making it a key player in changing how manufacturing works across different sectors.

Imagine a world where your design and production teams are perfectly synchronized, their efforts seamlessly aligned, and projects are completed ahead of schedule with minimal errors.

This isn't a distant dream but a reality that can be achieved through Product Lifecycle Management (PLM) software. Recent studies show that companies leveraging PLM software development experience up to a 20% reduction in time-to-market and a 30% increase in productivity. With such compelling statistics, it's clear that PLM software is revolutionizing how design and production teams collaborate.

In this ultimate guide to how PLM software enhances collaboration between design and production teams, you will discover the pivotal role PLM plays in bridging communication gaps, streamlining workflows, and ensuring project success.

This comprehensive guide will explore how PLM software facilitates real-time collaboration, integrates various functions, and supports efficient project management. Whether you're a project manager, a design engineer, or a production specialist, understanding the transformative power of PLM software is crucial for optimizing your team's performance and achieving operational excellence.

Chapter 1: Understanding PLM Software Fundamentals

Product Lifecycle Management (PLM) software refers to a suite of tools and technologies designed to manage a product's entire lifecycle, from initial concept through design, manufacturing, and service, until the product's retirement. PLM integrates people, processes, business systems, and information to facilitate efficient product development and management.

In the 1980s, PLM emerged from the need to handle complex product data and processes more effectively. Initially, PLM systems focused on managing design data and documentation. Over time, these systems evolved to encompass a broader range of functions, including supply chain management, project management, and collaboration tools. Today's PLM solutions offer advanced capabilities like real-time collaboration, data analytics, and integration with Internet of Things (IoT) technologies.

Visual Aids

To better understand PLM software, consider the following visual aids:

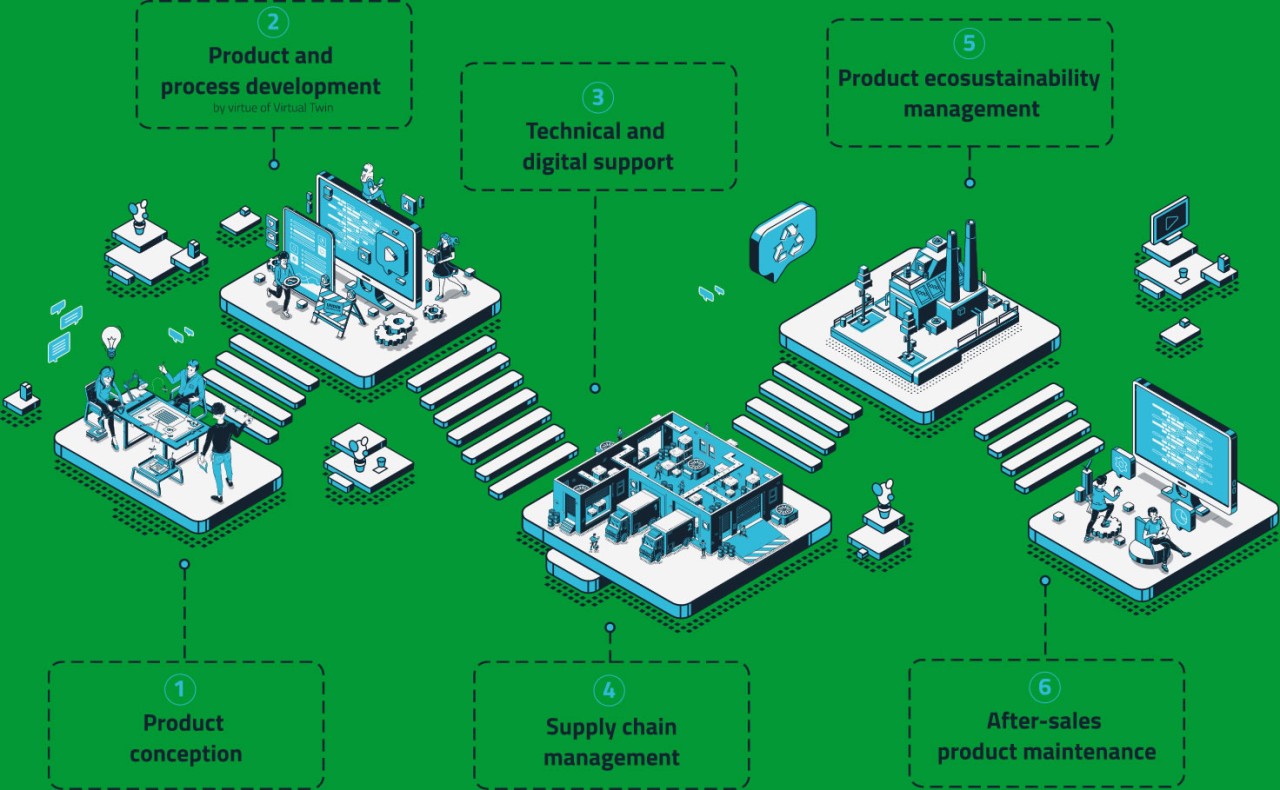

- PLM System Architecture Diagram: This diagram illustrates the core components of a PLM system, including product data management (PDM), collaborative product design, and lifecycle analytics.

- Product Lifecycle Infographic: An infographic that maps out the stages of a product lifecycle, highlighting how PLM software supports each phase from concept to end-of-life.

Importance

Understanding PLM software is essential for several reasons:

- Efficiency and Collaboration: PLM software streamlines workflows by centralizing product information enhancing collaboration between design, engineering, and manufacturing teams. According to a report by CIMdata, companies that implement PLM software report a 20% improvement in collaboration efficiency and a 15% reduction in time to market.

- Data Management: Effectively managing product data is critical in today's fast-paced market. PLM software helps organize and control product information, reducing errors and redundancies. Integrating a software engineering intelligence platform into the PLM system can enhance data accuracy and provide actionable insights to improve decision-making and product development efficiency. Research from Aberdeen Group indicates that 68% of companies with PLM solutions experience improved data accuracy and consistency.

- Innovation and Market Responsiveness: PLM software facilitates faster innovation by enabling teams to prototype, test, and iterate on designs rapidly. As noted by Gartner, organizations using PLM software are 30% more likely to bring innovative products to market faster than those without such systems.

- Regulatory Compliance and Quality Assurance: PLM software assists in maintaining compliance with industry standards and regulations, ensuring that products meet quality and safety requirements. This capability is crucial for industries like aerospace and automotive, where regulatory compliance is stringent.

By understanding the fundamentals of PLM software, organizations can leverage its capabilities to enhance efficiency, improve data management, and drive innovation. As product development complexity continues to increase, mastering PLM software becomes essential for staying competitive and achieving operational excellence.

Chapter 2: Getting Started with PLM Software

To effectively start using PLM software, it's crucial to first select a solution that meets your organization's needs, considering factors like features, scalability, and cost.

Once chosen, follow the vendor's installation guide to set up the software, either on your servers or in a cloud environment, and configure it to align with your processes. Create user accounts and assign roles and permissions based on team responsibilities. Import existing product data, ensuring its accuracy and accessibility, and integrate the PLM system with other enterprise systems like ERP and CAD tools. Provide comprehensive training for your team, utilizing manuals and online resources for ongoing support.

Finally, monitor system performance, gather user feedback, and continuously optimize the system to enhance efficiency. Common mistakes to avoid include inadequate planning, incomplete data migration, insufficient training, poor integration with other systems, and failure to adapt to evolving business needs.

By addressing these areas, you'll ensure a smooth implementation and effective use of PLM software.

PLM Software Platforms

- PTC Windchill: A leading PLM solution offering extensive features for product data management and collaboration.

- Siemens Teamcenter: Known for its robust integration capabilities and scalability.

- Dassault Systèmes' ENOVIA: Provides comprehensive tools for product design and lifecycle management.

- Autodesk Fusion Lifecycle: Ideal for cloud-based PLM solutions with strong collaboration features.

PLM Software List Resources

- CIMdata's PLM Resource Center: Offers whitepapers, webinars, and research on PLM best practices.

- Gartner's PLM Research: Provides market analysis and insights into PLM trends and vendors.

- PLM Global Network: A community of PLM professionals sharing knowledge and experiences.

- Autodesk's Learning Hub: A resource for tutorials and courses on Autodesk Fusion Lifecycle and related PLM tools.

Step-by-Step Guide

Getting started with PLM software involves several key steps. Follow this visual step-by-step guide to set up and begin using your PLM system effectively:

Choose Your PLM Solution

- Evaluate Needs: Assess your company's requirements and select a PLM solution that best fits your needs.

- Vendor Comparison: Compare different PLM vendors based on features, scalability, and cost.

Install and Configure

- Installation: Follow the vendor's installation guide to set up the PLM software on your servers or cloud environment.

- Configuration: Configure the software to match your organizational processes and requirements.

Set Up User Accounts and Permissions

- Create User Accounts: Set up accounts for all team members who will use the PLM system.

- Assign Roles and Permissions: Define roles and permissions based on user responsibilities to control access to different modules.

Import Existing Data

- Data Migration: Import existing product data and documents into the PLM system.

- Data Verification: Ensure that all data is correctly imported and is accessible.

Integrate with Other Systems

- System Integration: Connect the PLM system with other enterprise systems like ERP, CRM, and CAD tools.

- Test Integrations: Verify that all integrations are functioning correctly.

Train Your Team

- Training Programs: Organize training sessions for your team to familiarize them with the PLM software's features.

- User Guides: Provide access to user manuals and online resources for ongoing support.

Monitor and Optimize

- Performance Monitoring: Regularly monitor system performance and user feedback.

- Continuous Improvement: Make necessary adjustments and optimizations to improve efficiency and user experience.

Common Mistakes and Solutions

Inadequate Planning:

- Mistake: Skipping the planning phase can lead to poor implementation and user adoption.

- Solution: Conduct thorough needs assessments and planning to ensure the PLM system meets organizational goals.

- Mistake: Incomplete or inaccurate data migration can result in data loss and inconsistencies.

- Solution: Develop a detailed data migration plan and perform rigorous testing to ensure data integrity.

- Mistake: Insufficient training can lead to ineffective use of the PLM system.

- Solution: Invest in comprehensive training programs and provide ongoing support to users.

- Mistake: Failure to properly integrate PLM with other systems can disrupt workflows and data management.

- Solution: Ensure that PLM integrations are well-planned and tested thoroughly to align with existing systems.

- Mistake: Not adapting the PLM system to evolving business needs can limit its effectiveness.

- Solution: Regularly review and update the PLM system's configurations and processes to adapt to changes.

Chapter 3: The Future of PLM Software

Current Trends

The landscape of Product Lifecycle Management (PLM) software is rapidly evolving and driven by several key trends. One significant trend is integrating artificial intelligence (AI) and machine learning. These technologies enhance predictive analytics, enabling better forecasting and decision-making throughout the product lifecycle. According to a recent report by Deloitte, 45% of PLM users are already leveraging AI to optimize design processes and predict product performance.

Another major trend is the rise of cloud-based PLM solutions.

Another major trend is the rise of cloud-based PLM solutions.

Cloud platforms offer greater flexibility, scalability, and accessibility than traditional on-premises systems. Gartner's latest research indicates that over 50% of PLM deployments are now cloud-based, reflecting a shift towards more product lifecycle management agile and cost-effective solutions. This transition facilitates better collaboration across global teams by providing real-time access to product data and project updates.

The Internet of Things (IoT) is another trend shaping the future of PLM. IoT-enabled devices generate vast amounts of data that can be used for real-time monitoring and feedback, improving product performance and customer satisfaction.

A report by McKinsey highlights that companies incorporating IoT into their PLM strategies see a 25% increase in operational efficiency and a 15% boost in customer engagement.

Follow us and access great exclusive content everyday: Follow us on Google News

Challenges and Opportunities

As the PLM software landscape evolves, it brings forth a host of challenges. One such challenge is the paramount issue of data security and privacy, especially with the proliferation of cloud-based solutions and the integration of IoT devices. The need for robust cybersecurity measures and strict adherence to data protection regulations cannot be overstated. A study by Forrester found that 60% of organizations consider data security as their primary concern when adopting new PLM technologies.

Another challenge is the complexity of integrating new technologies with existing systems. Many companies need help aligning their PLM software with other enterprise systems like ERP and CRM. Addressing these integration issues will require advanced middleware solutions and a strategic approach to system architecture.

Despite the challenges, the future of PLM software is brimming with opportunities. The increasing use of AI and machine learning holds the potential to revolutionize product development processes, making them more intelligent and automated.

Not to forget, the rise of digital twins—virtual replicas of physical products—promises to enhance simulation and testing capabilities. As highlighted in a report by Accenture, companies using digital twins in their PLM processes have experienced significant reductions in development time.

The future of PLM software also holds opportunities for greater customization and user experience improvements. As technology advances, PLM systems will likely become more intuitive, offering personalized dashboards and user interfaces tailored to specific roles and needs.

So, while the future of PLM software presents challenges and opportunities, the ongoing advancements in AI, cloud computing, and IoT are set to transform how product development and lifecycle management are approached.

Embracing these trends and addressing potential hurdles will be vital in leveraging PLM software's full potential and maintaining a competitive edge in the evolving marketplace.

Chapter 4: How PLM Software Enhances Collaboration Between Design and Production Teams

You may also like: Best Apps for Employees: UPDATED 2022 – A Complete Guide

Real-Time Data Access and Sharing

PLM software excels at providing real-time data access to every team member involved in the product lifecycle. By centralizing information storage, all updates, new documents, and changes become instantly available, eliminating delays that typically occur when teams work in different systems or geographic locations.

Say, for example, that you own a fashion business. Here, traditionally, the design and production units operate in distinct silos. The adoption of fashion PLM software eradicates these silos by providing a unified platform for collaboration. Through this system, designers upload their most recent sketches and detailed specifications directly onto the PLM platform. This includes not just visual designs but also critical construction call-outs, precise measurements, and specific material placement instructions.

With this information centralized, production teams gain access in real time. They can instantly review these details and provide immediate feedback or suggest necessary modifications based on practical factors such as material availability or production capabilities.

Enhanced Project Management Features

Good project management is key to sticking to deadlines and budgets in product development. PLM software offers powerful tools that simplify setting deadlines, assigning tasks, and tracking progress. These tools help identify and solve problems early, so they don't derail the project. Also, being able to see the whole project at a glance helps everyone involved make better decisions and plan more effectively.

Managers can easily keep design and production teams on the same page, making sure everyone knows the deadlines and priorities. This helps keep projects on schedule and within budget, boosting overall efficiency and cost-effectiveness. Better communication between departments also encourages teamwork, which can lead to new ideas and better product designs

Free ebook: How To Get Your Intranet Off The Ground

Standardization of Processes

Another significant advantage of PLM software is its ability to standardize processes across different teams and locations. When design and production processes follow a standardized protocol, it significantly reduces the learning curve for new team members and decreases the likelihood of errors.

This consistency also helps in quicker integration of new technologies and methodologies into the existing workflow, keeping the company at the forefront of industry advancements. Moreover, standardization aids in better inventory management and resource allocation, optimizing both time and cost in production processes.

Standardization ensures that regardless of geographic and departmental divides, all teams follow the same procedures, use the same formats, and adhere to identical compliance standards, which enhances overall operational efficiency. This uniformity also supports more accurate reporting and analysis, enabling leadership to assess performance and make data-driven improvements effectively.

Integrated Feedback Mechanisms

Feedback mechanisms integrated within PLM software facilitate a continuous improvement culture. Designers and production teams can utilize these tools to suggest improvements, flag issues, and validate that all modifications align with the original design requirements and production capacities.

This feedback is invaluable for iterating on product designs in real time, allowing for adaptive changes that can lead to a better fit with market demands and consumer expectations. Furthermore, these mechanisms encourage a participatory approach among stakeholders, which can increase job satisfaction and a sense of ownership among team members.

Compliance and Quality Control

Using PLM software makes it easier to stick to industry standards and manage quality control. The software keeps a record of every change made during product development, making sure that designs and production meet both regulatory requirements and internal quality checks. This level of transparency helps build trust with clients and regulatory bodies by clearly showing that all rules are followed. It also speeds up the certification process with external organizations, saving time and effort.

This record-keeping is key during audits and helps sort out any differences between the planned design and the final product. By making sure everyone follows the set guidelines, PLM software reduces the chance of breaking rules and improves the overall quality of the final product. Better quality control means fewer product recalls and happier customers, which can boost the company's reputation and profitability.

Chapter 5: What are the benefitsEnter heading here...

Product Lifecycle Management (PLM) offers numerous benefits that enhance the efficiency and effectiveness of product development and management processes:

- Improved Collaboration: PLM centralizes product data, enabling better communication and collaboration among cross-functional teams such as design, engineering, and manufacturing.

- Streamlined Processes: By standardizing workflows and automating tasks, PLM reduces redundant work and accelerates the product development cycle.

- Enhanced Data Management: PLM systems provide a single source of truth for product data, ensuring consistency and accuracy across all stages of the product lifecycle.

- Increased Innovation: With tools for real-time feedback and advanced analytics, PLM fosters innovation by allowing teams to quickly test and iterate on new ideas.

- Better Quality Control: PLM helps in tracking compliance with industry standards and regulations, improving product quality and reducing the risk of costly recalls.

- Cost Reduction: By optimizing resources and reducing waste, PLM can lead to significant cost savings throughout the product lifecycle.

- Faster Time-to-Market: Efficient management of product data and processes enables quicker decision-making and faster delivery of products to market.

- Scalability and Flexibility: Modern PLM systems, especially cloud-based solutions, offer scalability and flexibility to accommodate the changing needs of growing businesses.

- Enhanced Customer Satisfaction: By improving product quality and ensuring timely delivery, PLM helps in meeting customer expectations and boosting satisfaction.

- Comprehensive Reporting and Analytics: PLM systems provide valuable insights through comprehensive reporting and analytics, aiding in strategic planning and continuous improvement.

Wrapping up

In summary, adopting Product Lifecycle Management (PLM) software profoundly enhances the collaboration between design and production teams. By facilitating real-time communication, standardizing procedures, and integrating feedback, PLM software effectively addresses many common challenges in product development. These improvements lead to streamlined workflows, better project management, and ultimately, the creation of high-quality products that stand out in the market.

The benefits of implementing PLM software extend beyond mere process improvements. Companies that leverage PLM solutions can drive innovation more effectively, as the system supports seamless integration of new ideas and technologies. This capability not only accelerates time-to-market but also ensures that products meet high standards of quality and compliance. For businesses looking to optimize their product development processes and enhance operational efficiency, investing in a robust PLM system is a strategic move that promises substantial returns.

Chapter 6: Frequently Asked Questions

What is PLM Software?

PLM Software, or Product Lifecycle Management software, is a tool that manages a product's entire lifecycle—from conception and design to manufacturing, service, and retirement. It integrates people, processes, and information across the product development cycle to improve efficiency, collaboration, and innovation.

How Does PLM Software Improve Collaboration?

PLM Software enhances collaboration by centralizing product data and providing a single platform for all team members to access and update information. This integration reduces silos, ensures real-time updates, and facilitates communication between design, engineering, and production teams, leading to faster decision-making and fewer errors.

What Are the Key Features of PLM Software?

Key features of PLM Software include product data management, version control, document management, workflow automation, and integration with other enterprise systems like ERP and CRM. Advanced systems also offer capabilities like real-time analytics, AI-driven insights, and IoT integration for enhanced monitoring and optimization.

How Can I Choose the Right PLM Solution for My Business?

Choosing the right PLM Solution involves evaluating your specific needs, such as the size of your organization, the complexity of your products, and your integration requirements. Consider factors like scalability, ease of use, and vendor support. It's also helpful to request demonstrations and seek feedback from other users in your industry.

What Are Common Challenges When Implementing PLM Software?

Common challenges include data migration issues, user resistance, and integration difficulties with existing systems. To overcome these challenges, it's important to plan thoroughly, provide adequate training, and ensure robust support from the PLM vendor. Engaging stakeholders early and setting clear objectives can also help mitigate these issues.

How Does PLM Software Integrate with Other Enterprise Systems?

PLM Software integrates with other systems such as ERP, CRM, and CAD tools through APIs and middleware. These integrations facilitate data exchange and synchronization across platforms, ensuring consistent information and streamlined processes. Effective integration helps in maintaining a unified view of product data and improves overall operational efficiency.

What Are the Benefits of Cloud-Based PLM Solutions?

Cloud-Based PLM Solutions offer benefits like scalability, flexibility, and cost-effectiveness. They allow for easier access from anywhere, improved collaboration among global teams, and reduced IT overhead since the vendor manages the infrastructure. Cloud solutions also often come with built-in updates and security features that ensure the latest capabilities and protection.

How Does AI Enhance PLM Software?

AI Enhances PLM Software by providing advanced analytics, automating routine tasks, and offering predictive insights. AI can help in identifying trends, optimizing designs, and improving decision-making processes. For example, AI-driven tools can predict potential product failures and suggest design improvements, leading to faster innovation and better product quality.

Categories

Blog

(2726)

Business Management

(333)

Employee Engagement

(213)

Digital Transformation

(185)

Growth

(124)

Intranets

(121)

Remote Work

(61)

Sales

(48)

Collaboration

(43)

Culture

(29)

Project management

(29)

Customer Experience

(26)

Knowledge Management

(21)

Leadership

(20)

Comparisons

(8)

News

(1)

Ready to learn more? 👍

One platform to optimize, manage and track all of your teams. Your new digital workplace is a click away. 🚀

Free for 14 days, no credit card required.